Monitoring Solutions

Solutions for making, storing and transmitting measurements from HotSense™ ultrasonic transducers.

Automated Wireless ultrasound

Intrinsically safe Hotsense™ sensors.

Automated Wireless Ultrasound for on-stream corrosion, erosion and wear monitoring. Track wall loss rates, detect changes and see into the future to optimize operations and reduce outages

Measurement Hub

HotSense™ Measurement Hub for low cost, manual data collection from installed ultrasonic probes Improve measurement precision through reduced operator variability and enable data trending to facilitate predictive and preventative maintenance of critical assets.

Field Data Logging Kit (FDLK)

HotSense™ Field Data Logging Kit (FDLK) for Automated Ultrasonic Measurement Logging. For the rapid deployment and management of HotSense™ WirelessHART ultrasonic projects and data collection.

Sensors

Installed ultrasonic probes for applications including wall thickness, corrosion, erosion and gas void detection.

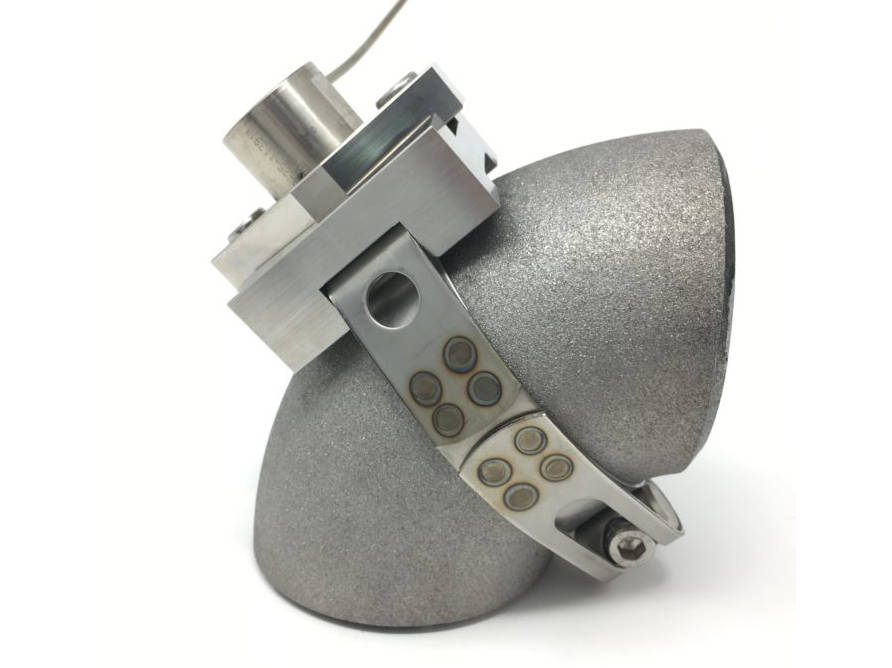

HotSense™ 150 Dual Element

Reduce the cost and complexity of on-stream ultrasonic monitoring.

Dual element ultrasonic transducer for on-stream thickness, corrosion and erosion monitoring for use in applications across refining, oil & gas, energy, nuclear, aerospace, and process sectors.

HotSense™ 380

Minimize operational risk and maximize productivity with enhanced asset intelligence.

Ultrasonic transducers for 0-degree measurements ideal for thickness, corrosion and erosion monitoring for use in applications across refining, oil & gas, energy, nuclear, aerospace, and process sectors.

HotSense™ UHT

Sensors for In-Service Wall Thickness Monitoring Up To 550°C (1022°F)

Minimize operational risk and maximize productivity with enhanced asset intelligence